Showing all 4 results

Shrink tunnel series

Why Choose Our Shrink Wrap Machine?

Quality Assurance

Our shrink wrap machines guarantee high production efficiency. They use heat to shrink wrap single or bundled products, ensuring a secure and professional finish. These machines are perfect for a wide range of products like bottles, boxes, toys, electronics, stationery, cosmetics, and beverages.

Variety of Machines

We offer several types of shrink wrap machines:

Shrink Tunnel Machines: Ideal for heat shrink films such as POF, PVC, and more. Adjustable temperature and conveyor speed cater to different packaging needs. The machine height can be adjusted based on the size of the packaging item. The Teflon conveyor retains heat effectively, ensuring high efficiency and accurate temperature control.

2 in 1 Shrink Wrap Machine: Combines sealing and heat shrinking in one step. The transparent cover allows visibility of the sealing, cutting, and shrinking process. Suitable for POF, PVC, and other packaging materials. This model offers low electricity consumption and an automatic electric magnet-absorbed cover.

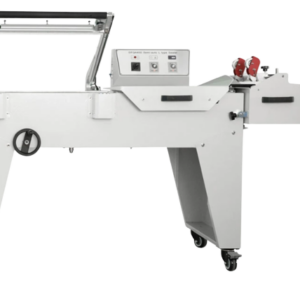

L-Type Sealer Machines: Available in a normal version and a semi-automatic version with a conveyor. Made in Taiwan, these machines use impulse heat with special electrothermal wires and porcelain, providing neat and quick sealing. They are easy to use, assemble, and repair. The semi-auto version can automatically convey products into a shrink tunnel through a conveyor belt after sealing and cutting.

Benefits of Shrink Tunnel Machines

Superior Protection

Shrink wrap provides a tight seal around items of various shapes and sizes, protecting them from dust, dirt, and moisture. This high level of protection ensures that products remain safe during shipping.

Durability

Shrink wrap is made from strong, long-lasting plastic that resists ripping and piercing. It remains tight and secure even in adverse weather conditions, providing enhanced security. The resilience of shrink wrap ensures that it does not deteriorate or loosen over time, maintaining its tight seal under harsh conditions. This durability keeps items safe during long-distance travel or through multiple distribution hubs.

Cost Efficiency

Shrink tunnel machines require only shrink film and heat, making the process cost-effective. The price of plastic depends on its quality, but the overall cost remains lower than the value it provides. Shrink wrap also helps bundle items together, maximizing space and reducing costs for storage and transport.