Showing all 9 results

Sealer series

Why Choose Our Sealing Machines?

Our sealing machines are easy to operate with heat and suitable for sealing various plastic films. We offer a range of models including hand stamping machines, foot step sealing machines, continuous band sealer machines, and L-type sealer machines.

Hand Sealing Machines

Hand sealing machines are widely used to seal all kinds of plastics including plastic films, compound films, and aluminum plastic films. Industries such as food, tea, medicine, and hardware often use these machines. Weighing only 4.5 kg, they are small, portable, and ideal for low-volume packing. The sealing length is 300 mm, and the thickness is 3 mm.

Foot Step Sealing Machines

Our foot step sealing machines efficiently seal various heat-sealed packaging bags, including aluminum foil bags, plastic bags, compound bags, kraft paper, fresh keeping bags, and tea bags.These machines are suitable for the food, chemical, agriculture, and other industries. Operated by foot, they come in two sizes: 450 mm and 650 mm, with a sealing thickness of 8 mm. An intelligent temperature controller ensures precise control.

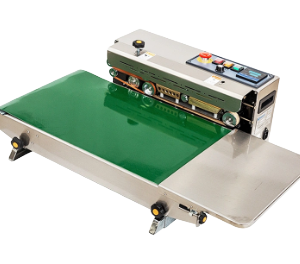

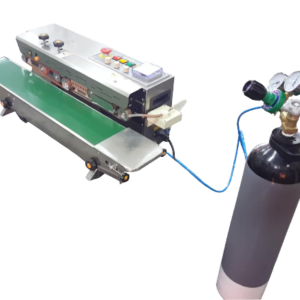

Continuous Sealing Machines

Continuous sealing machines are ideal for medium to high-volume packing of small packages like aluminum foil bags, kraft paper, fresh keeping bags, plastic bags, and tea bags. They offer adjustable sealing speed and temperature based on film thickness for high-quality sealing. The sealing thickness is 14 mm. Available in vertical and horizontal models, the vertical model is suitable for liquid packaging with a maximum conveyor loading of 3 kg.

L-Type Sealing Machines

L-type sealing machines create packages enclosed with shrink film. These machines primarily seal books, stationery, bottles, gift packets, and cosmetic boxes. Made in Taiwan, they are highly dependable and come with a warranty and after-sales services. They are adjustable to any size and are popular for their powerful electronic timer, taking only 2-3 seconds for sealing.

Benefits of Our Sealing Machines

Our sealing machines offer numerous benefits:

- Can seal a variety of materials including kraft paper, plastic, and aluminum foil.

- Suitable for various industries such as commerce and manufacturing.

- Simple and easy to operate.

- Helps preserve perishable items and prolongs shelf life.

- Hand sealers are easy to carry, weighing less than 10 kg.

- Foot step sealing machines allow hands-free operation, enabling the operator to handle packaging easily.

- Continuous sealing machines provide firm sealing, high efficiency, and low power consumption. They also print and seal simultaneously with embossed expiry or manufacture dates.