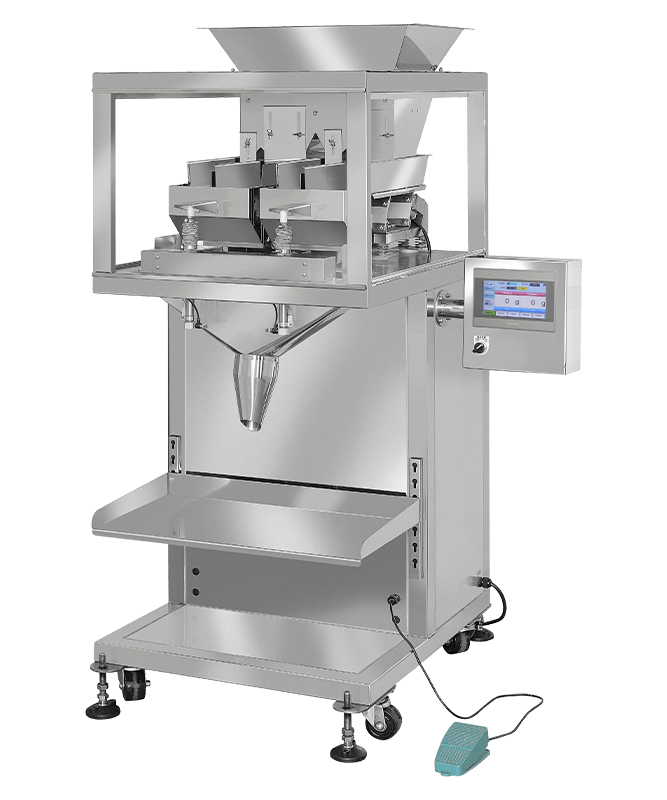

Powder Filling Machine – Everything You Need to Know

A powder filling equipment allows many businesses to quickly and accurately fill containers with powdered products. This machine easily handles dry materials such as flour, spices, or baby formula. It operates at high speeds and performs repetitive tasks without errors. Using this machine helps companies save significant time and labour. Instead of filling containers by hand, workers can rely on the machine to manage the entire process, which boosts productivity and helps businesses stay on schedule.

In this blog, you will learn how the machine functions, the different types available, the benefits it offers, and key considerations for selecting the right one for your needs.

What is a Powder Filling Machine?

A powder filling machine moves dry or fine materials into jars, pouches, or bottles. It helps you get the same amount in every container. This tool works fast and doesn’t let powder spill or spread. Some machines weigh the powder, while others measure how much space it takes. Companies that package food, medicine, or cleaning powders often use these machines. The machine keeps things clean and reduces mess during work. In places like Malaysia, many businesses use a powder filling equipment to fill containers fast and keep their process smooth. Picking the correct machine helps your workflow run better and makes packing easier.

Benefits of Using a Powder Filling Machine

Saves Time and Increases Speed

A powder filling machine moves faster than any person could. It pushes powder into many containers without stopping. Workers can do other jobs while the machine fills each pack. This boosts how much you can finish in a short time. Instead of pouring one container at a time, the machine keeps moving. You can complete more tasks in a day and ship products quicker to your buyers.

Offers Accurate Filling with Less Waste

A powder filling machine Malaysia makes sure each pack gets the same amount. You don’t need to guess or check each one. This stops you from using too much or too little powder. It also helps avoid spills and saves your product. Everything stays neat. This machine helps your packaging look smart and keeps your customers happy.

Works Well with Different Powder Types

Some powders flow fast. Others move slowly or stick to surfaces. A good powder filling machine handles both types. It doesn’t get blocked or stuck. It works with powders used in food, medicine, or cleaning products. You can set it to match how your powder behaves. That way, it pours without clumps or slowdowns.

Reduces Labour Costs and Boosts Efficiency

When workers fill containers by hand, it takes time and many people. A powder filling machine does the job with fewer people. One person can run the machine while others work elsewhere. This saves money and time. It also helps people avoid doing the same task over and over, which can be tiring.

How Does a Powder Filling Machine Work?

The powder filling tool starts by holding powder in a big bin called a hopper. Then, it guides the powder into a tube that leads to the container. A turning screw or weight system controls how much powder drops into each container. You can set how much you want it to fill. Some machines even come with screens to help you change settings. An automatic powder filling machine fills containers faster and more smoothly. In Malaysia and other places, these machines often use smart parts that help measure powder and fill containers evenly, without spilling or wasting anything.

Types of Powder Filling Machines

Auger Powder Filling Machine

This type uses a spiral screw to carry powder into containers. It turns the screw to guide the powder through a small space. It works well for dry or fine powders like flour. In addition, it gives steady results every time.

Pros: Accurate filling, handles most powders, easy to run.

Volumetric Powder Filling Machine

This machine fills containers by space, not by weight. It uses a set amount of space to drop powder. It fills quickly, but not always perfectly. In addition, it works best with powders that don’t stick or clump.

Pros: Fast action, simple to use, budget-friendly.

Weighing Powder Filling Machine

This machine fills by using weight. It places the right amount into each container by checking on a scale. It works well when you must be exact, such as in medicine or health products.

Pros: High precision, great for costly powders, and very little waste.

Automatic Powder Filling Machine

This machine fills, caps, and sometimes labels containers without much help. It runs fast and fits places where many products move through each day. It saves time and effort for busy factories.

Pros: High speed, saves worker time, and consistent results.

Applications of Powder Filling Machines

Food Industry

In food work, these machines fill containers with powder-like spices, sugar, or powdered milk. The machine helps keep the powder dry and safe. It fills the right amount into each pack. That way, the product looks clean and well-made on the shelf.

Pharmaceutical Industry

Medicine companies use powder filling tools to measure and pack powdered drugs and supplements. These machines fill bottles or pouches with the correct dose. They keep the workspace clean and help avoid mistakes in medicine amounts.

Cosmetic Industry

Face powders, body powders, and beauty clays also come in powder form. A powder filling machine helps pack these items neatly. It prevents mess and fills jars or boxes without air bubbles or gaps. The product stays smooth and clean.

Chemical Industry

Chemical powders like soap, cleaner, or lab powder need clean filling too. These powders may be sticky or fine, but the machine controls how they move. This helps avoid spills or dust, keeping workers safe and packing steady.

Buying Guide – How to Choose the Right Powder Filling Machine

Know Your Product Type

Each powder moves differently. Some powders fill like water, while others clump together or move slowly. You need to choose a machine that matches how your powder acts. That helps the machine work better and fill faster without stopping.

Choose the Right Capacity

Think about how many containers you need to fill each day. If you fill only a few, a small machine works fine. But if you fill many, get a bigger or automatic powder filling machine. Make sure the machine can keep up with your daily tasks.

Look for Easy Operation and Cleaning

A good machine should be simple to use. The buttons and parts should be clear and easy to reach. After use, the machine must be easy to clean. This saves time and keeps the powder from mixing with new batches.

Consider After-Sales Support and Parts

Machines sometimes need fixing or new parts. Choose a company that helps you after you buy. Powder filling machine Malaysia suppliers often offer quick service and extra parts. This keeps your work moving and avoids long delays.

Maintenance & Safety Tips for Powder Filling Machines

Clean your machine after each use. Empty all the powder, then wipe parts with a dry cloth or brush. Don’t let powder sit in the machine for too long. That can cause clogs or rust. Check screws and belts every week and keep things tight. Teach your workers how to use the machine the right way. Always unplug the machine before cleaning. Don’t let water touch electric parts. Keep the area around the machine dry and clear. These small actions help the machine last longer and work safely each time.

Common Challenges & Solutions

Sometimes the powder blocks the machine. You can fix this by changing the parts or adjusting the speed. If powder spills, make sure the container sits in the right place. Use sensors to stop the machine when the container moves. Sticky powder may need better airflow or smoother paths. If the fill amount keeps changing, check the weight system or screw. Tighten anything loose. Most problems stop if you check the machine often. Buying the right powder filling machine helps you avoid many issues from the start.

Conclusion

A powder filling tool makes your work quicker and smoother. It fills containers with care and speed. You waste less and pack more in less time. These machines work well for food, medicine, makeup, and cleaning powder. You can find one that fits your needs, whether you work in a small shop or a large business. From augers to automatic powder filling machines, every type offers special help. If you work in Malaysia or anywhere else, using the right powder filling machine can help your business grow. Pick wisely, care for your machine, and you will see how much easier your work becomes.