Showing all 4 results

Shrink Wrap Machine Series

Shrink Wrap Machines

Shrink wrap machines are essential packaging tools that apply heat to shrink plastic film tightly around products, offering protection, durability, and enhanced presentation.

What is a Shrink Wrap Machine?

A shrink wrap machine is an essential packaging solution used to apply a plastic film around products and shrink it tightly using heat. The process ensures a secure, professional finish that improves both product presentation and protection. These machines are widely used across various industries, from food and beverages to electronics and pharmaceuticals.

Types of Shrink Wrap Machines

Choosing the right shrink wrap machine depends on your product size, volume, and production needs. Here are the main types:

1. Shrink Tunnel Packing Machine

This machine is ideal for heat shrink films such as POF and PVC. It features adjustable temperature and conveyor speed to cater to different packaging requirements. The machine’s height can be modified based on the size of the packaging item. Its Teflon conveyor retains heat effectively, ensuring high efficiency and precise temperature control.

2. 2 in 1 Shrink Tunnel Machine

Combining sealing and heat shrinking in a single step, this machine reduces electricity consumption and simplifies the packaging process. It is easy to handle and requires only one operator, making it economical for low-volume production. Suitable for shrink films like POF, PVC, and PP, it offers a transparent cover for visibility during the sealing, cutting, and shrinking process. The machine also features an automatic electric magnet-absorbed cover.

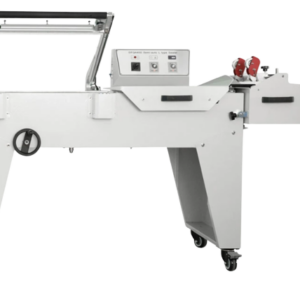

3. L-Type Sealer Machine

This machine uses impulse heat with special electrothermal wires and porcelain to provide neat and quick sealing. Made in Taiwan, it is easy to use, assemble, and repair. The L-Type Sealer Machine is suitable for sealing various products and offers a maximum sealing length of 450 x 450mm. It operates on 110v/220v/240v with an impulse power of 1500w and weighs 25 kg.

4. Semi-Auto L-Type Sealer (with Conveyor)

An enhanced version of the L-Type Sealer Machine, this semi-automatic model includes a conveyor belt that automatically conveys products into a shrink tunnel after sealing and cutting. It is designed for higher efficiency and is suitable for medium to high-volume packaging operations.

5. Manual and Automatic Systems

- Manual Machines: Operated by hand, ideal for low-volume use.

- Automatic Machines: Perform sealing, cutting, and shrinking with minimal human input. Perfect for high-output production lines.

Factors to Consider When Buying a Shrink Film Wrapping Machine

Before investing in a Shrink Film Wrapping Machine, consider the following key factors:

1. Production Volume

Assess how many units you need to package daily. Low-volume operations may suffice with manual or semi-automatic machines, while larger facilities should opt for automatic systems.

2. Product Dimensions

Measure your typical product size. Ensure the machine can accommodate your widest and tallest products, including grouped or bundled items.

3. Film Type Compatibility

Shrink wrap machines work with various films, such as PVC, Polyolefin, and Polyethylene. Confirm that your machine is compatible with the desired material for your industry needs.

4. Heating Capacity

Look for adjustable temperature control. Efficient heating ensures a tighter wrap and prevents film burn or wrinkles.

5. Build Quality and Durability

Choose machines made from strong materials like stainless steel. Durable machines require less maintenance and last longer, especially in industrial settings.

6. Speed and Efficiency

Packaging speed affects your workflow. Higher speeds mean greater output. Select a machine that matches your operational pace without compromising on sealing quality.

7. Safety Features

Safety is vital. Look for features like emergency stop buttons, insulated covers, and overheating protection to safeguard workers and equipment.

Common Applications of Shrink Wrap Machines

Shrink wrap machines are versatile and used in many sectors. Common applications include:

Retail Products

Items such as cosmetics, electronics, and toys benefit from tamper-proof, visually appealing packaging.

Food Industry

Shrink wrapping preserves freshness and protects products like baked goods, dairy, and frozen meals during transport and display.

Pharmaceuticals

Sealing medicines and medical devices ensures hygiene, tamper resistance, and compliance with regulatory standards.

Beverage Industry

Shrink tunnels are used to bundle bottles or cans in multipacks for easier handling and branding.

E-commerce and Logistics

Shrink wrap offers secure packaging for individual or grouped products, reducing damage during transit and enhancing professionalism.

Why Choose AutoPak Shrink Tunnel Machines?

At AutoPak Trading, our shrink tunnel series machines are engineered for durability, efficiency, and precision. With models designed to meet a range of business sizes and applications, we offer:

- Adjustable speed and temperature controls

- Stainless steel construction for long-term use

- Compatibility with multiple film types

- Compact designs for space-saving installations

- Simple operation with minimal training required

Our machines help businesses streamline packaging, reduce waste, and improve product appeal.

Ready to transform your packaging line?

Upgrade your packaging process with the right shrink wrap machine. Whether you’re starting small or scaling up, AutoPak Trading has a solution tailored to your needs.