Showing all 5 results

Strapping Machine Series

Why Choose Our Strapping Machine?

Our strapping machine is mainly used in packaging and binding of paper cartons, wooden cases, paper parcels, etc.

Variety of Models

We have various models of strapping machines in Malaysia such as semi-automatic strapping machines, fully automatic strapping machines, semi-auto pallet strapping machines, and semi-auto carton sealing machines.

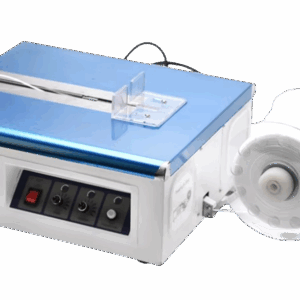

Semi-Automatic Strapping Machines

For semi-automatic strapping machines, after the strapping band is inserted, the cycle will start automatically. Our machine will dispense, tension, seal, and cut the strap automatically. They have an integrated board control system to ensure precise bonding and high availability. Auto motor shut off after pausing for the present time, energy saving.

Models of Semi-Automatic Strapping Machines

We offer two types of models for this semi-automatic strapping machine which are high table (AP 707) and low table model (AP 708). The main difference between these two models highly depends on customer usage.

High Table vs. Low Table Models

We recommend a low table for large and heavy products because the height of the machine will make it easier for clients to place heavy items in lower height machines. For high tables, we recommend general products. The height difference for these two models is around 250mm. In terms of function and operation, these two models offer the same thing.

Strapping Bands

For strapping bands, our machine can use 9mm, 12mm, and 15mm. The best seller strapping band is 15mm and we sell two types of material which are recycled and new material. Polypropylene (PP) strapping tape is cost-effective and easy to use.

Fully Automatic Strapping Machines

For our fully automatic strapping machines, take premium 1 grade tape as binding material. You just need to press a button and it will finish strapping automatically.

Models of Fully Automatic Strapping Machines

We offer two models for fully automatic strapping machines which are AP 102 and AP 101. The AP 102 model uses a DC motor. The maximum packing size is (W)800mm X (H)600mm. The AP 101 model uses an AC motor. The maximum packing size is (W) 850mm x (H)600MM. You also can use the printing tape to improve the image of the product.

Semi-Auto Pallet Strapping Machine

For our semi-auto pallet strapping machine, it is a vertical machine system. This model is suitable for large and heavy things, only takes 1.5 seconds for strapping one polypropylene strap.

Benefits of Using Strapping Machines

The benefit of using a strapping machine is to improve productivity. Products can be strapped more quickly as well as more consistently. Your staff can quickly adjust the tension of the machine, which also leads to less damage to the product. This machine also offers savings in the cost of strapping tape because less strapping tape is required. It will cut the strap precisely to the tension. Strapping machines are also safe and easy to operate, helping to reduce employee injury concerns that can come with hand packaging techniques. You will be able to save at least one labour cost when you invest in a strapping machine.

Cost Efficiency

For the cost of the machine, we sell a different variety depending on your budget. However, you will quickly recoup this investment cost by saving your business time and money in the long run.