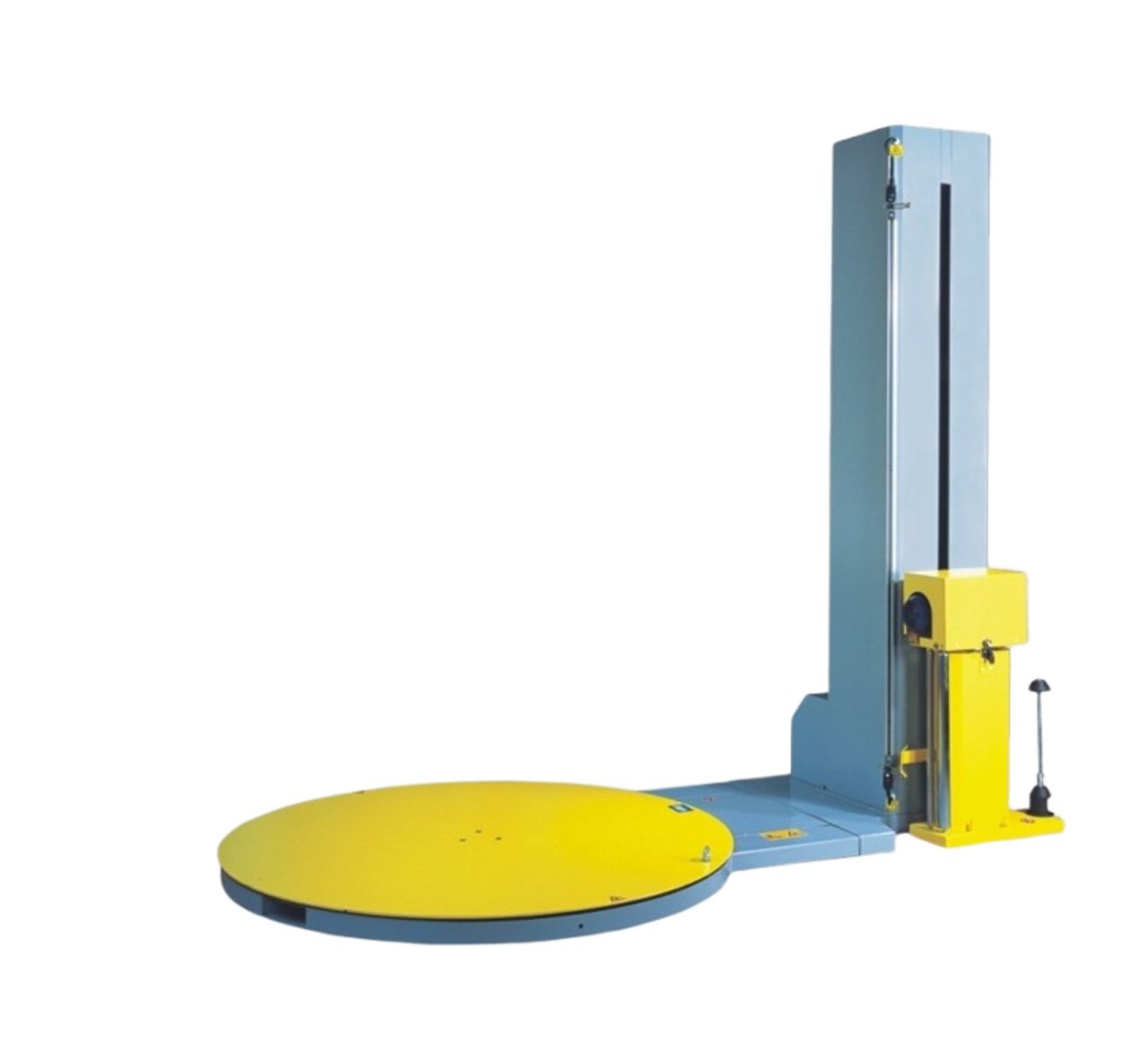

| Model | Pallet Wrapper Machine |

|---|---|

| Turntable Diameter | 1500mm (1200 x 800mm) |

| Pallet Height/Weight | 700-1200mm / 1500kg |

| Turntable Height | 80mm |

| Power Supply | 110v/220v 50Hz/60Hz 1 phase |

| Weight | 400 KG |

Why Choose Our Pallet Wrapper?

Fully Automatic Pallet Wrapping Machine

The pallet wrapping machine from AutoPak Trading offers an efficient solution for businesses managing high-volume packaging. With precision control, reliable performance, and user-friendly operation, this automatic pallet wrapper reduces material waste and increases productivity.

Built to perform in demanding environments, our stretch wrapping machine is ideal for industries like logistics, food, manufacturing, and retail. It ensures secure load stability while reducing human effort and downtime.

Types of Pallet Wrapping Machines

Choosing the right pallet wrapping machine starts with understanding its types. Each model suits different packaging needs.

Turntable Pallet Wrapper

This type rotates the pallet on a platform while the film dispenser stays fixed. It’s a common choice for standard load sizes and stable products. Our model includes a 1500mm diameter turntable, suitable for loads up to 1500kg.

Rotating Arm Wrapper

Here, the arm moves around a stationary pallet. This design is ideal for very heavy or unstable loads. It also supports integration into automated lines.

Semi-Automatic Wrappers

These machines require manual film attachment and cycle initiation. They are suitable for medium output operations.

Fully Automatic Pallet Wrappers

Our automatic pallet wrapper operates independently once loaded. The system detects pallet height and wraps with precision. This model is built with an advanced PLC control system for consistent results.

Key Benefits of Using a Pallet Wrapping Machine

A quality stretch wrapping machine brings measurable benefits to operations. It improves safety, lowers cost, and supports consistent packaging standards.

Improved Efficiency

The automatic pallet wrapper handles multiple loads without stopping. It shortens cycle time and supports uninterrupted production. This translates to faster deliveries and less labour dependency.

Reduced Film Usage

Our pallet wrapping machine pre-stretches film by up to 250%. It reduces plastic use and helps you meet sustainability goals while saving on material costs.

Enhanced Load Stability

Uniform wrapping improves load integrity during transport and storage. Whether shipping overseas or stacking in warehouses, stability ensures fewer damaged goods.

Lower Labour Costs

With only one operator required, businesses can reallocate staff to higher-value tasks. This reduces risk and enhances workforce productivity.

Versatility Across Industries

The pallet wrapping machine suits industries like electronics, food, hardware, ceramics, and chemicals. It handles diverse shapes and packaging demands.

How to Choose the Right Pallet Wrapping Machine

Selecting the correct pallet wrapping machine depends on several factors. These include the type of products you handle, volume, and space limitations.

Assess Load Size and Weight

Ensure the machine can manage your pallet size and load weight. Our standard model handles up to 1500kg with a maximum pallet height of 1200mm.

Consider Speed Requirements

If you handle large orders daily, an automatic pallet wrapper will improve throughput. Machines with higher turntable speed and faster film carriage offer better performance.

Integration Options

Look for machines that integrate with your existing line. AutoPak models offer PLC compatibility and can be adapted for ERP or labelling systems.

Maintenance and Support

Choose a machine from a supplier with good after-sales service. AutoPak Trading offers a one-year warranty and local technical support.

How to Maintain a Pallet Wrapping Machine for Longevity

Regular maintenance is essential to ensure your stretch wrapping machine operates reliably. Preventive care extends the machine’s service life and reduces unexpected downtime.

Daily Checks

Inspect film tension, rollers, and the sensor system. Clear any debris around the turntable. Check for signs of wear on moving parts.

Schedule Regular Servicing

Plan maintenance based on operating hours. Lubricate bearings and replace worn belts. A service interval every 3 to 6 months is advised for high-use machines.

Keep Software Updated

Our automatic pallet wrapper includes programmable logic controls (PLC). Keep firmware updated and calibrate settings periodically.

Train Operators

Ensure your team knows how to operate and troubleshoot the machine. A trained operator will use the system efficiently and prevent damage.

Why Choose AutoPak Trading

AutoPak Trading offers reliable, high-performance pallet wrapping machines designed for the demands of modern industry.

Heavy-Duty Engineering

Our pallet wrapping machines are built with robust materials designed for long-term industrial use. They perform reliably under demanding conditions.

Versatile Application

From food and beverage to electronics and building materials, our stretch wrapping machines are suited for a wide range of industries and load types.

High Pre-Stretch Efficiency

With a film pre-stretch capability of up to 250%, our machines reduce plastic use while maintaining strong load security—lowering overall packaging costs.

Advanced PLC Control

Each automatic pallet wrapper includes a smart PLC system, allowing precise control, custom settings, and consistent wrapping quality across all loads.

Compact and User-Friendly Design

Designed for space-saving installation, our models feature an intuitive interface and quick-start operation—requiring minimal training.

Reliable Support and Warranty

We offer a one-year warranty, full technical support, and fast response times. AutoPak Trading is committed to long-term partnerships with every customer.