Showing all 2 results

Carton Sealer

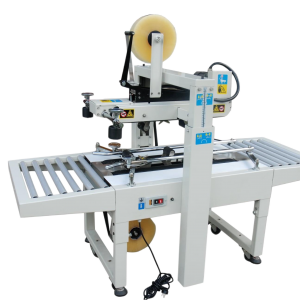

Carton Sealer Machines

Carton sealer machines are essential tools in modern packaging operations. They provide consistent, secure box sealing using tape, helping businesses reduce labour costs and increase productivity. This guide covers everything you need to know about these machines, including types, features, uses, and benefits.

What Is a Carton Sealer?

A carton sealer is a machine used to seal the top and bottom of cardboard boxes using adhesive tape. It reduces the time and effort needed to close boxes by hand. These machines are commonly used in warehouses, production lines, and distribution centres.

They improve consistency and packaging quality. They also help reduce waste and damage during delivery by ensuring every box is securely sealed.

Types of Carton Sealer Machines

There are different types of carton sealers. Each type fits different business needs based on volume, box size, and automation.

Semi-Automatic Carton Sealer

This model is best suited for businesses with moderate packaging needs where operators can handle some manual steps. The machine seals both the top and bottom of the box using O.P.P. tape.

Key Specifications:

- Maximum Carton Size: 500 x 600 mm

- Minimum Carton Size: 180 x 130 x 150 mm

- Sealing Speed: 20 metres per minute

- Machine Dimensions: 1520 x 790 x (960–1650) mm

- Machine Weight: 150 kg

- Operation: Manual folding of flaps and manual box placement required

- Applications: Mid-range packaging tasks for small to medium operations

This model is suitable for businesses sealing a consistent number of cartons daily but without the demand for full automation.

Fully Automatic Carton Sealer

This advanced model is designed for high-volume packaging environments, where speed and efficiency are top priorities. The machine adjusts to different box sizes and closes all flaps automatically.

Key Specifications:

- Maximum Carton Size: 600 x 500 x 500 mm

- Minimum Carton Size: 250 x 150 x 180 mm

- Machine Dimensions: 2270 x 1030 x (1705–1945) mm

- Operation: Fully automatic – no manual adjustment needed

- Features: Auto flap folding, automatic tape application, high output

- Applications: Large-scale operations and integration with production lines

This machine is ideal for businesses processing over 200 cartons per day and looking for full automation to boost output and consistency.

Key Features to Consider When Buying a Carton Sealing Machine

When choosing a machine, it’s important to focus on features that match your operation’s needs. The right machine will improve speed, reduce waste, and lower costs.

1. Box Size Range

Check the machine’s maximum and minimum box size. Some machines handle only fixed dimensions, while others adjust to multiple sizes.

2. Tape Type and Width

Most machines work with BOPP or kraft tape. Ensure the model supports the tape size you plan to use. Tape width can affect sealing strength and appearance.

3. Sealing Speed

Speed is measured in boxes per minute or metres per minute. Higher speeds suit large operations. For smaller businesses, a moderate speed is often enough.

4. Build and Frame Quality

Machines with a solid steel frame last longer and perform better. A strong build helps with stability and reduces the need for repairs.

5. Automatic Adjustments

Some models detect box dimensions and adjust automatically. This feature is useful when boxes vary in size. It saves time and reduces the chance of error.

6. Maintenance and Support

Choose a machine with accessible parts and clear instructions. Regular maintenance keeps the machine in good condition. Reliable after-sales service is also important.

7. Safety Features

Look for machines with emergency stop buttons, safety guards, and sensors. These reduce the risk of injury in busy workplaces.

Industries That Use Carton Sealer Machines

Carton sealing machines are used across many sectors where packaging speed, consistency, and protection matter. Below are key industries that benefit from these machines and how they apply them in daily operations.

1. E-commerce and Retail

Businesses in e-commerce rely on fast, reliable packaging to handle large order volumes while keeping costs low. Carton sealers support this by automating the box sealing process.

- Handles high-volume packaging during peak seasons.

- Ensures consistent branding with printed tape.

- Speeds up fulfilment with reduced manual labour.

- Lowers the risk of packaging errors.

Improves unboxing experience for customers.

2. Food and Beverage

In the food sector, safety, hygiene, and speed are critical. Carton sealers help ensure safe transit of products from warehouses to retailers or end customers.

- Supports clean and hygienic sealing.

- Works well in chilled or frozen environments.

- Secures delicate or perishable items.

- Reduces time in packaging lines.

Maintains compliance with food handling standards.

3. Electronics and Appliances

Fragile items need solid, tamper-proof packaging. Carton sealers provide the strength and precision required for the electronics industry.

- Protects against damage in transit.

- Offers strong seals for heavy boxes.

- Prevents tampering and moisture exposure.

- Works with shock-absorbing packaging.

Enhances product presentation and security.

4. Pharmaceuticals and Healthcare

Precision and safety are key in pharma packaging. Carton sealers help maintain product integrity and meet strict regulations.

- Maintains seal integrity to prevent tampering.

- Supports traceability and labelling.

- Reduces manual handling errors.

- Provides hygienic packaging solutions.

Meets compliance for transport and storage.

5. Manufacturing and Distribution

Large-scale manufacturing and logistics centres use carton sealers to streamline operations and scale production output.

- Speeds up large-batch packaging.

- Integrates with conveyor and sorting systems.

- Reduces human labour on repetitive tasks.

- Handles diverse box sizes and shapes.

- Cuts down tape usage and material waste.

Benefits of Using a Carton Sealing Machine

Higher Efficiency

Machines work faster than people. This increases output and helps meet demand during busy periods.

Cost Reduction

Sealers use less tape and reduce the need for staff on the packaging line. This lowers material and labour costs.

Professional Finish

Taped boxes look neat and uniform. This improves your product’s appearance and builds trust with customers.

Better Safety

Automated sealing reduces strain on staff. It also improves safety by removing repetitive movements.

Scalability

As your business grows, your packaging needs increase. A machine helps you scale operations without hiring more workers.

Maintenance Tips

- Keep the machine clean and free of tape residue.

- Check the blades and rollers regularly.

- Replace worn parts as needed.

- Follow the manufacturer’s service guide.

Regular care extends the machine’s life and ensures smooth operation.

Get the Right Sealer for Your Business

Explore our range of carton sealers today. Whether you’re a small company or a large manufacturer, we have a solution that fits your needs.